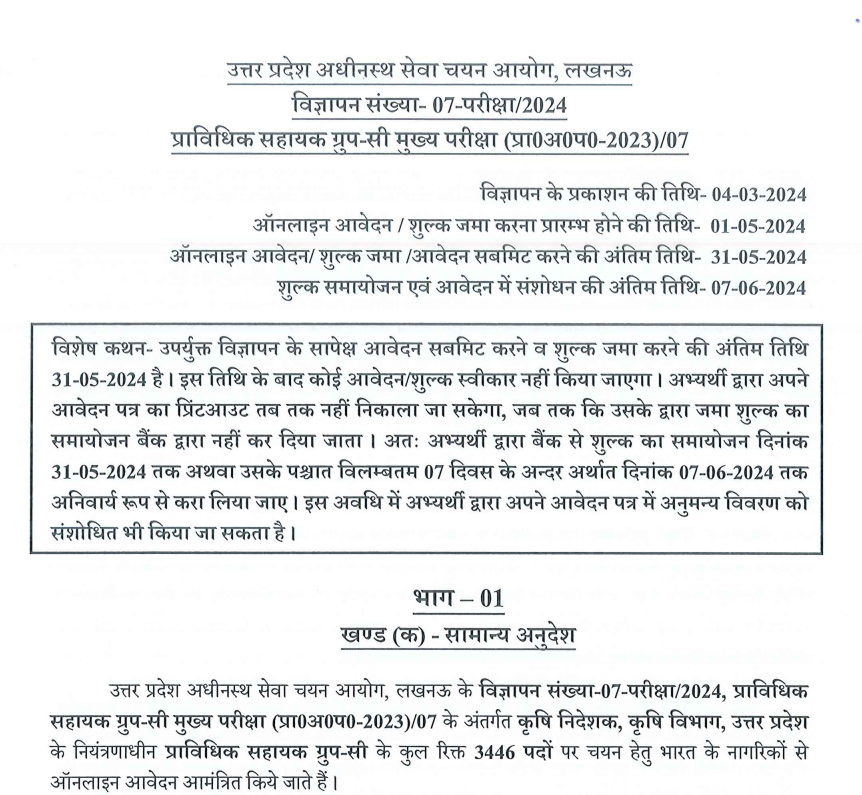

Production management and Industrial Part 1

Category –ME Online Test

Telegram-Join Us On Telegram

Attempt Free Production management and Industrial Part 1 Here. Read The Important Mechanical MCQ From Below.

Q1. Job evaluation is the method-of determining the

A. relative worth of jobs

B. skills required by a worker

C. contribution of a worker

D. contribution of a job

Answer : A

Q2. The chamfering is an essential operation after.

A. knurling

B. rough turning

C. boring

D. thread cutting

Answer : D

Production management and Industrial Part 1

Q3. Micro motion study is

A. analysis of a man-work method by using a motion picture camera with a timing device in the field of view

B. motion study observed on enhanced time intervals

C. motion study of a sequence of operations conducted systematically

D. study of man and machine conducted simultaneously

Answer : A

Q4. Per cent idle time for men or machines is found by

A. work sampling

B. time study

C. method study

D. work study

Answer : A

Q5. TMU in method time measurement stands for

A. time motion unit

B. time measurement unit

C. time movement unit

D. technique measurement unit

Answer : B

Production management and Industrial Part 1

Q6. Time study is

A. the appraisal, in terms of time, of the value of work involving human effort

B. machine setting time

C. time taken by workers to do a job

D. method of fixing time for workers

Answer : A

Q7. Work sampling observations are taken on the basis of

A. detailed calculations

B. convenience

C. table of random numbers

D. past experience

Answer : C

Q8. One time measurement unit(TMU) in method time measurement system equals

A. 0.0001 minute

B. 0.0006 minute

C. 0.006 minute

D. 0.001 minute

Answer : B

Production management and Industrial Part 1

Q9. Basic motion time study gives times for basic motions in ten thousandths of

A. second

B. minute

C. hour

D. day

Answer : B

Q10. Choose the wrong statement. Motion study is used for

A. improving a work method

B. improvising a work method

C. designing a work method

D. providing a schematic framework

E. reducing inventory costs.

Answer : E

Q11. Gnatt chart provides information about the

A. material handling

B. proper utilisation of manpower

C. production schedule

D. efficient working of machine

Answer : C

Production management and Industrial Part 1

Q12. ABC analysis deals with

A. analysis of process chart

B. flow of material

C. ordering schedule of job

D. controlling inventory costs money

Answer : D

Q13. Process layout is employed for

A. batch production

B. continuous type of product

C. effective utilization of machines

D. all of the above

Answer : A

Q14. For a product layout the material handling equipment must

A. have full flexibility

B. employ conveyor belts, trucks, tractors etc.

C. be a general purpose type

D. be designed as special purpose for a particular application

Answer : D

Production management and Industrial Part 1

Q15. Travel charts provide

A. an idea of the flow of materials at various stages

B. a compact estimate of the handling which must be done between various work sections

C. the information for changes required in rearranging material handling equipment

D. an approximate estimate of the handling which must be done at a particular station

Answer : B