Utilization of Electrical Energy MCQ PDF 2

Category –EE Online Test

Telegram-Join Us On Telegram

Attempt Free Utilization of Electrical Energy MCQ PDF 2 Here. Read The Important Electrical MCQ From Below.

Utilization of Electrical Energy MCQ PDF 2

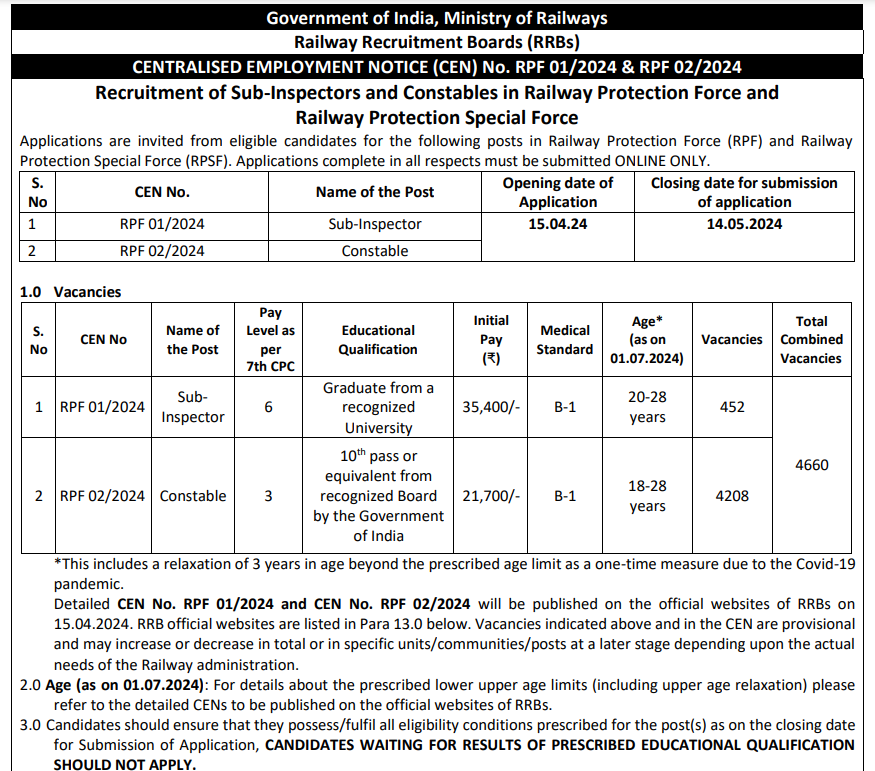

Utilization of Electrical Energy is a important subject for RRB,SSC and others AE,JE & Technician exam, In this subject Today we are providing Electric Welding MCQ 2,In upcoming days we will cover Illumination, Electric heating, Electroplating, Electric drives and motors.

1) If the blowpipe is moved to and fro frequently while cutting the kerf will

- not be affected

- be less

- of correct size

- be more

Answer-4

2) In gas cutting, if too little cutting oxygen is supplied

- the metal will be cooled down

- the kerf will be narrow

- the kert will be wide

- the metal will fail to cut completely

Answer-4

3) The top edge is melted round and the cutface is not smooth in gas cutting. This is due to

- extremely slow cutting speed

- insufficient acetylene pressure

- the tip being held too high

- too much cutting oxygen pressure

Answer-3

Utilization of Electrical Energy MCQ PDF 2

4) In a gas cut plate, the cut shows groove sand has deep drag lines. This is due to

- tip too close to the cut surface

- too much travel speed

- less oxygen pressure

- smaller size cutting nozzle

Answer-1

5) In a gas cut plate, the cut is high quality although there is some surface roughness caused by vertical drag lines. This is due to

- too slow cutting speed

- smaller size cutting nozzle

- impure cutting oxygen

- less preheating flame

Answer-1

6) The size of the cutting nozzle used in oxyacetylene cutting process depends mainly on

- thickness of metal to be cut

- purity of oxygen

- duration of cut

- type of cutting blowpipe

Answer-1

7) Which of the following types is not fillet weld

- T-joint

- Corner joint

- lap joint

- butt joint

Answer-4

8) Double-V and double-U butt welds are used for plates of thickness

- 1 – 5 mm

- 5 – 10 mm

- 10 – 15 mm

- above 15 mm

Answer-4

Utilization of Electrical Energy MCQ PDF 2

9) Which material is not used for making non-consumable electrodes

- Carbon

- Tungsten

- Graphite

- Sodium

Answer-4

10) Which of the following is an example of plastic welding

- Gas welding

- Arc welding

- Thermit welding

- Forge welding

Answer-4

11) Which of the following is not a type of arc welding

- Submerged

- Plasma

- Air-acetylene

- Electro-slag

Answer-3

12) Which of the following is an example of fusion welding

- Arc welding

- Resistance welding

- Thermit welding with pressure

- Forge welding

Answer-1

Utilization of Electrical Energy MCQ PDF 2

13) Which of the following welding process is used for welding of sheet metals in automobile and air craft industries

- Resistance welding

- Thermit welding

- Gas tungsten arc welding

- Shield metal arc welding

Answer-1

14) In which of the following process, heat is created by blacksmith fire

- Seam welding

- Spot welding

- Projection welding

- Forge welding

Answer-4

15) Heat is created by chemical reaction in

- Tungsten arc welding

- Thermit welding

- Oxy-acetylene welding

- Resistance welding

Answer-2

16) In resistance welding, two electrodes are made of

- Copper

- Iron

- Bronze

- Aluminium

Answer-1

Utilization of Electrical Energy MCQ PDF 2

17) Acetylene can be prepared by the chemical reaction between

- Hydrogen and Calcium carbide

- Water and Calcium carbonate

- Water and Calcium carbide

- Hydrogen and Calcium carbonate

Answer-3

18) Which flame is suitable for cutting operations

- Oxidising flame

- Carburising flame

- Neutral flame

- None of these

Answer-1

19) Which flame is suitable for welding steel

- Oxidising flame

- Carburising flame

- Neutral flame

- None of these

Answer-2

20) Which of the following is not true for gas welding

- There are safety problems in storing and handling the gases

- Heat effected zone and distortion are less as compare to arc welding

- It is slower than arc welding

- It is suitable for thin sheets

Answer-2